|

CONTACT US |

SHOP |

LINKS |

Plating Kits |

Aluminum Anodizing |

Powder Coating |

Plug n' Plate ®. (Brush Plating) |

Polishing and Buffing |

Repair Products |

|---|

CHROME PLATING KITS, NICKEL PLATING KITS, ZINC PLATING KIT, COPPER PLATING KIT, GOLD PLATING, BOTH ELECTROPLATING AND ELECTROLESS PLATING. AS WELL AS POLISHING SUPPLIES AND POWDER COATING. Caswell Plating Australia sells every plating kit possible for the home DIY plating experience. Caswell Australia provides expert local knowledge and expertise to allow the home plater using our home plating kit, powder coating guns or polishing supplies to achieve professional electro plating or metal finishing results from home.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Motor Size |

Wheel Diameter |

||||

|

4” |

6” |

8” |

10” |

12” |

1/6 hp |

1” |

5” |

- |

- |

- |

1/4 hp |

1.5” |

1” |

5” |

- |

- |

1/3 hp |

2.5” |

2” |

1” |

- |

- |

1/2 hp |

3” |

2.5” |

2” |

1” |

- |

3/4 hp |

4.5” |

3.5” |

2.5” |

2” |

1” |

2 hp |

4.5” |

4.5” |

4.5” |

3” |

1.5” |

The table above show the THICKNESS of wheels. You may use multiple wheels to make up total permissible width.

There are two basic buffing motions you should use.

| 1. CUT MOTION gives you:- SMOOTH SURFACE, SEMI-BRIGHT & UNIFORM. The workpiece should be moved AGAINST the direction of the wheel, using a MEDIUM to HARD pressure. |

|

| 2. COLOR MOTION gives you:- BRIGHT, SHINY & CLEAN SURFACE. The workpiece should be moved TOWARD the direction of the wheel, using a MEDIUM to LIGHT pressure. |  |

The correct pressure must be applied to the workpiece to provide the best finish economically and safely. Inadequate pressure will give NO buffing action.

Excessive pressure will cause the buffing wheel to slow down or actually collapse. This can also result in burn marks on the workpiece.

For best results your wheel should maintain a surface speed of between 3600 & 7500 Surface Feet Per Minute. (SFPM). The higher your speed, the better and quicker your results.

Formula for calculating surface speed of wheel in SFPM.

SFPM = 1/4 x diameter of Wheel x RPM (revs of spindle per min.)

Therefore an 8” wheel @ 3600 RPM =2 x 3600 = 7200SFPM. Spindle speeds can be increased by a step pulley on a motor shaft.

For the workshop where only the occasional piece of work needs to be buffed, an economic alternative to purchasing a special machine is to simply adapt a bench grinder. Whilst this does not have the extended shaft, it can still do a formidable job.

All the guards need to be taken off and the grinder mounted on the edge of a workbench. This will allow access to the wheel from many angles. Alternatively, a small used washing machine motor can be used. With access to a lathe, a simple pointed taper can be made to fit over the shaft. Then the buffing wheels can be aimed on to the point. On smaller pieces, an electric drill with one of our shank mounted buffs will do an excellent job.

Some of our customers have even placed a large hand grinder in a vice, then changed the grinding wheel for a buff. These machines usually have very high speeds with good power, so they should be considered as another option.

Whenever you are making up something to do a buffing job, your prime consideration should be your safety.

If the buff pulls the piece from your hands, you should consider where it is likely to go. Remember it will be traveling at a fair speed, so no one should be in its way!

Is the machine mounted safely? It will have to stand a fair amount of abuse, so make sure it is WELL fastened down.

DISCLAIMER - Buffing machines can be dangerous. We accept no liability for their use/misuse or for accidents caused by the removal of guards.

There are two distinct areas on a buffing wheel -

THE UNSAFE AREA which is rotating towards the workpiece.

THE SAFE AREA which is rotating away from the workpiece.

The division of these two areas is marked with the dotted line on the above drawings. The workpiece must only be applied to the area of the buff that is rotating AWAY from the workpiece.

You should ensure that you are completely aware which area is which, otherwise you could have a serious accident. Objects being thrown away from a buffing wheel can be traveling at very high speeds, which can result in some very unpleasant and potentially deadly accidents!

When buffing parts have sharp corners, edges or hooks, they should be offered to the wheel with the edge flowing away from the buff, so the part does not catch. Operators should ALWAYS wear SAFETY GOGGLES, APRON, GLOVES and DUST MASK.

We often get asked, 'Which grit should I use first?” Unfortunately, there is no cut and dried answer to this, because it really depends on the condition of the part. So, lets discuss some examples:

1) Aluminum Side Cover with one deep scratch.

To successfully remove the scratch, ALL of the material around the scratch has to be disposed of. In our example, this means a lot of aluminum! Initially, we are concerned with getting as much aluminum sanded off as quickly as possible, so we would use the coarsest abrasive available, say a 40 grit sandpaper on a flat block. It would be of NO USE to try to buff out this deep scratch with a buffing wheel, because the wheel would remove more material from the hole, as well as the surrounding areas. By keeping the abrasive on a flat block, no further material can be removed from the hole.

As the scratch is lessened, the grit size of paper is reduced from 40, to 80, 120, 240, 320 and finally 600. Once the surrounding material is removed, then the actual polishing can be started.

Buffing compounds will be determined by the size of the scratches. If you have used a 600 grit paper, you may like to proceed directly to a white buffing compound. If fine scratches are visible, then you'll need to 'back off' and go to the black compound before retrying the white.

2. Aluminum Side Cover - just dull.

Obviously, it would be a step backwards to start treating this piece by using the technique in our first example. As there is no large metal content to be removed, you could virtually dispense with the sandpapers and move directly to the polishing aspect of the part. The Brown buffing compound with a spiral sewn wheel could be employed to see if the shine is good enough. If not, then use a black compound, and then rework the part using the brown compound.

3. Aluminum Wheel Casting.

Many wheels are prepainted, directly over a rough sand casting. Remove the paint using VHT Stripfast, to expose the aluminum. The 'pimples' caused by the sand cast have to be removed to flatten the metal ready for polishing. Because of the difficult contours of the wheel, it is virtually impossible to sand with a flat block, so this is where Greaseless Compound comes in. Start off with the 80 grit, using a spiral sewn wheel or, for the awkward areas, a felt bob. Then proceed through the various grit sizes of Greaseless, until the metal is smooth , all 'pimples' are removed and an even 'flat' finish is achieved. The polishing should only begin once all traces of 'pimples' are gone. Use Black Compound for most of the polishing work, and finally, on a fresh or cleaned wheel, buff lightly with the Brown compound.

Use this chart to determine which wheels and compounds to use to polish different metals. This is a guide...experienced polishers will vary the materials used to suit the application and their technique. This chart serves as a good starting point for beginning polishers, but feel free to experiment.

BLACK = Emery Compound, a course abrasive material for removal of scratches, pits, paint,

rust etc.

BROWN = Tripoli compound used for general purpose cut and color on most soft metals.

WHITE = Blizzard compound, used for color and final finish of harder metals, has a cutting action.

RED = Jeweller’s Rouge, designed to polish without any cutting action. Safe on thin plates. Use

on its own wheel.

BLUE = A dryer, almost greaseless wheel - designed to polish without any cutting action. Safe

on thin plates. Use on its own wheel.

GREEN = Used exclusively for Stainless Steel.

THE THREE BUFFING STAGES

A = Rough Cut To Remove Scratches

B = Final Cut & Initial Polish - At Stage B, you should first use your wheel with a cutting action, then finish with a color action.

C = Final Polish (or luster)

|

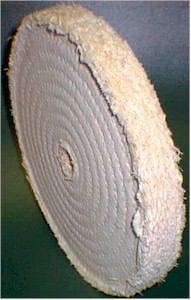

Sisal is a slender, hard, cellular strand of fiber that has demonstrated its great strength and tough resiliency in the form of binder twine, cord & rope for many years. These qualities, along with its natural abrading and grease absorbing characteristics, provide an ideal buffing wheel fabric. Sisal buffing wheels will provide both polishing and cutting action. They will remove stretcher strains, orange peel, polishing wheel grit lines, light die marks, etc. To effect a fast cut, use a sisal wheel with the Black Emery compound or any of the greaseless compounds. |

|

Spiral sewn wheels are the workhorse of most buffing and polishing jobs. Because the plies of cotton cloth are sewn together spirally, the wheel becomes much harder and more pressure can be exerted on it. This is especially useful when ‘cutting’ the metal. The faces of these |

|

The main purpose of a loose cotton wheel is to polish and cut in a similar manner to the Spiral sewn wheel, except that this wheel, not being tightly stitched together, will ‘mush’ or collapse, allowing the |

|

Canton Flannel is a very soft material, and therefore is ideal for polishing items where a gentle touch is needed. Canton Flannel wheels are used in the jewelry trade to polish items with gold or silver plating, where no removal of metal is desired. They can also be used to polish plastic and lacquered items such as guitars. |

|

Domet Flannel is the softest buffing material available. It can be used in any situation where an extremely soft touch is required. |

|

Our newest buffing wheel, the denim buffing wheel, is soft enough for any buffing application that calls for cotton wheels, but, because of the sturdy denim construction, it lasts much, much longer than a cotton buff. The faces of these wheels are pre-raked to accept |

|

These buffs are specially treated to give longer life than standard buffs. This treatment makes them much harder than regular cotton buffs, which allows the user to exert more pressure onto the wheel and gets the job done faster. Use with any compound just like |

|

These buffs are sewn with two rows to slightly stiffen the buff.This improves the speed of the final coloring operation, giving you performance somewhere between a spiral sewn and a loose wheel. |

|

These buffs are specially treated to give longer life than standard buffs. They cut and color faster and are vented to keep the workpiece cooler. Hard center allows fast mounting to tapered spindle for quick change. Use with any compound. |

|

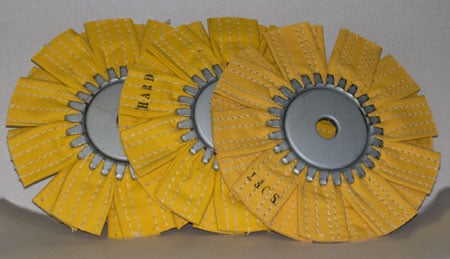

The folded pleats hold more compound and keep the part cooler, resulting in a being twice as fast as a Spiral Sewn wheel. 10” wheels require 3” washers. These wheels are softer than their yellow cousins. |

|

Thousands of thin cotton string strands will buff all types of plastics, including bacolite, to a shiny surface. The buff is specially designed to keep the plastic cool. Bring side markers, turn signals, tail light lenses to shiny, like new condition. Thousands of 1-3/4” long cotton strands reach deep into details to gently polish and shine without overheating and melting plastic. Use in conjunction with our Plastic Glo Compound. |

|

An aggressive wheel, designed to buff irregular contoured metals, especially useful for buffing of checker plate. The treated sewn cloth fingers penetrate into crevices etc. and at the same time reduce friction eat buildup, so reduces the possibility of distorting thin metal panels etc. Use with Greaseless or black emery compounds. The wheel comes with a 5/8” hole in the metal center. ½” inserts are available. |

|

With a thickness of 2”, this long lasting wheel is an economic alternative to stacking sisal wheels on a shaft. The fibers are treated and stiff, giving an excellent hard surface for the initial cut to de-burr etc. Use with Greaseless compounds or Black Emery |

|

Diameters are 2.5, 3.5 & 4.5 inches. |

|

Diameters are 2.5, 3.5 & 4.5 inches. |

|

The pointed end is ideal for buffing inside holes and crevices, like the lug nut holes in wheels. Made from soft cotton. Use with any compound. |

|

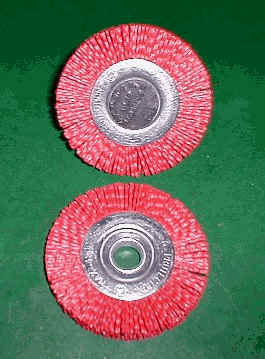

Ideal for buffing contoured shapes such as wheels. Scrubber wheels remove rust, scratches, minor blemishes, old paint, and plating. Use a light touch. No compound is required, as |

|

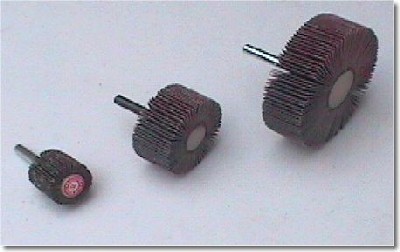

These tightly packed and bonded sheets of resin bonded aluminum oxide are great for sanding, shaping and polishing all types of materials. Especially good for removing paint and rust. Best |

|

Strands of nylon impregnated with a tough aluminum oxide abrasive. Removes old paint, rust, weld scale and burns. Cleans and polishes. Is ideal for wood because it cleans without gouging. It never loses its abrasive power, or its shape. Safe on |

|

We developed a special buffing wheel that fits straight into a drill chuck. The unique shape allows the buff to rest on the pipe without spinning off. By simply rotating the drill, all angles of the pipe can be buffed rapidly. The tapered end allows you to get into difficult corners. This buff is ideal for almost any tubing, such as handrails on boats, handlebars, tail pipes etc. Use with almost any buffing compound, but is especially useful with Blue Begone liquid polish. |

There are lots more tips and tricks in our FREE Buffing Booklet. Download The Complete Booklet - 730 KB

.